SERIES PIPE & PROFILES CRUSHER SERIES

Project profile

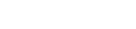

XMP Series pipe section bar crusher rotor diameter is 600mm, multiple rotor width options Overall heavy welded

service hotline:+86-769-85096969

Detail description

XMP Series pipe / section bar crusher rotor diameter is 600mm, multiple rotor width options. Overall heavy welded steel hopper into the crushing chamber fixed angle with the horizontal and extends through the hopper feeding tubes and profiles is easy. Standard V-shaped cutting technology, Help to improve the efficiency and reduce the cutting recycling the dust content of recycled materials. Other standard equipment also includes the crushing cavity is easy to disassemble and bearing may reduce the risk of external contaminants from entering the crushing chamber.

Traditional crusher in operation do not apply to broken pipes and profiles of the long, long recovery for the size and bulk materials. Generally require feeding platform, the company developed the XMP series crusher designed close to the level of the feed hopper, easy to grow the size of the material feed. The machine during operation without the risk of blocking material, when the full stop after the material into the crushing chamber cavity emptied again until solid material and continue crushing.

- Special design of the rotor angle can be automatically fed into the hopper of the tube or profile drag crushing chamber.

- Reliable security

- Heavy solid rotor bearing mounted outside the crushing chamber, avoiding the body cavity into the bearing scrap lead to bearing damage, thereby protecting the crushing chamber and tool.

| Mode | XMP600/600 | XMP600/800 | XMP600/1000 | |

| Drive power | kw | 37 | 45 | 75 |

| Rotor diameter | mm | 600 | 600 | 600 |

| Rotor width | mm | 600 | 800 | 1000 |

| Number knife | 5*2 | 5*2 | 5*2 | |

| Number knife | 2*1 | 2*2 | 2*2 | |

| Size | mm | 500*430 | 700*430 | 900*430 |

| Crushing cavity diameter | mm | 600*560 | 800*560 | 1000*560 |

| Weight | kg | 4000 | 5000 | 6000 |

| Dimensions | L*W*H mm | 2450*1500*1850 | 2450*1700*1850 | 2450*2000*1850 |

Keyword:

Next page:POWERFUL CRUSHER SERIES

Previous page:Claw knife type crusher series